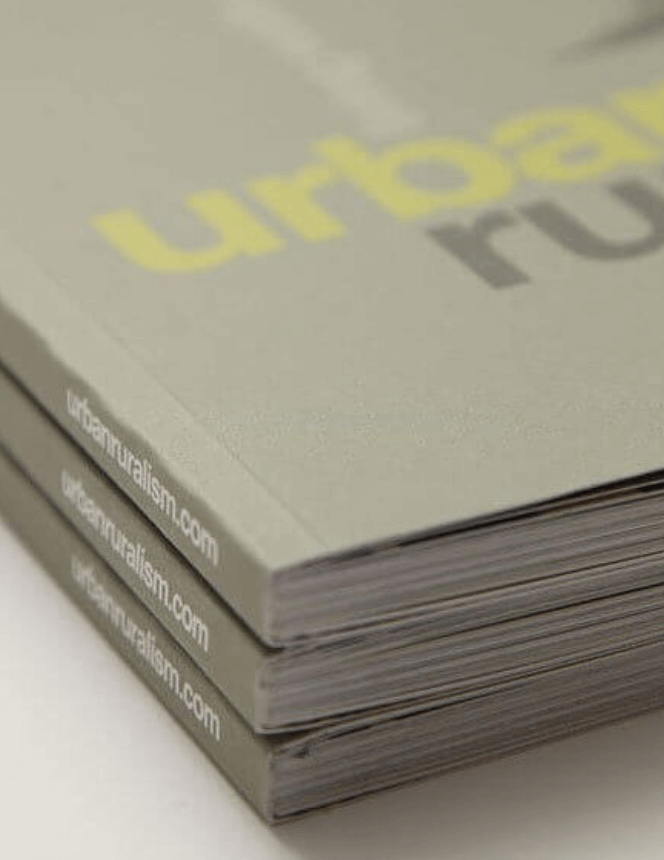

Glued Notched Section

Also known as notch binding, glued notched section binding is a variation of perfect binding used in publication production. This method is designed to create a stronger bond than traditional perfect binding by notching or cutting grooves along the spine of the book block before the adhesive is applied. These notches increase the surface area for the glue to adhere to, resulting in a more durable bind.

Glued notched section binding offers many benefits over standard perfect binding. The notches create a stronger bond between the pages and the cover, making the book more durable and less likely to have pages fall out with heavy use. It can be used on multiple publications, such as hardcover books, manuals and paperback books.

Get the best bindery for your print project with glued notched section binding!

As a trade printing expert, we take each binding process very seriously, so that your clients’ demands go beyond their expectations. Here’s an general overview of the glued notched section binding production process:

Printing and Collating: As with perfect binding, the process begins with printing the text of the book on large sheets of paper, which are then cut down to size and divided into small groups of pages, or signatures. These signatures are collated in the correct order.

Notching the spine: Unlike traditional perfect binding, where the spine is milled to create a rough surface, in glued notched section binding, the spine of the collated signatures is cut with several small notches or grooves. These notches can be made using various methods, including sawing or using a special notching machine.

Applying the glue: A strong, flexible adhesive is applied to the spine, filling the notches. The type of glue used is typically a hot-melt or polyurethane-reactive (PUR) adhesive. PUR provides a stronger and more durable bond and is often preferred for higher-quality books.

Attaching the cover: The cover, which is a single piece of printed paper or cardstock, is then wrapped around the glued spine and the gathered pages. The cover is usually slightly larger than the book block to allow for trimming.

Pressing and Curing: The book is placed in a press to ensure a tight bond between the pages and the cover. If PUR adhesive is used, it requires some time to cure and achieve full strength.

Trimming: The three open sides of the book are trimmed after the glue has dried and the book is removed from the press. This step gives the book clean, sharp edges and ensures that it opens properly.

Quality check and finishing touches: The finished books are inspected for quality. Additional steps, such as adding fold-out covers, flaps, or embossing, can be done depending on the design of the book.

Low startup quantity (minimum 500)

Available on 100% recycled paper

Available with Glossy and matt finish

Available in custom sizes